ŘETĚZY VAMBERK offers a complete range of conveyor chains and the production of conveyor chains is a major part of our production program. We manufacture and supply a complete range of conveyor chains FV according to DIN 8165, M according to DIN 8167, ISO 1977 and CSN 26 0401, SMS according to Swedish standard SMS 1698 and BS according to British standard BS 4116/4. Furthermore, special conveyor chains of various designs and dimensions.

Range of conveyor chains

Conveyor chains to DIN 8165, M to DIN 8167, ISO 1977 and CSN 26 0401, SMS to Swedish standard SMS 1698 and BS to British standard BS 4116/4.

Conveyor chains with deep link plates FV to DIN 8165, M to DIN 8167, ISO 1977 and CSN 26 0401, SMS to Swedish standard SMS 1698 and BS to British standard BS 4116/4.

Conveyor chains - full radius - for protection against damage of transported material. Widely used in the timber and furniture industry.

Conveyor chains with hollow pins FV to DIN 8165, M to DIN 8167, ISO 1977 and CSN 26 0401 and BS 4116/4. On request with higher breaking load, welded pins, bigger clearances or in stainless steel.

Conveyor chains FV, M, SMS and BS with attachments in a wide range. On request, we can produce any shape, size and arrangement of attachments. Welded or bended design.

Scraper chains FV, M, SMS and BS in all sizes. Welded or bended versions on request. Various materials including stainless steel. Also in sets with crossbars or plastic wipers.

3W conveyor chains with extended service life in the winter conditions of northern Europe, Siberia and Canada.

WAX conveyor chains with increased wear resistance and extended service life of up to 300%.

We will gladly meet your requirements for design, dimensions, raw materials, lubrication, heat and surface treatment of chains.

Conveyor chains with welded pins and bushes with increased shock resistance and extended service life. For any conveyor chain.

Conveyor chains with bigger clearance and corrected pitch for increased resistance to shock, transported material, dirt and wearing.

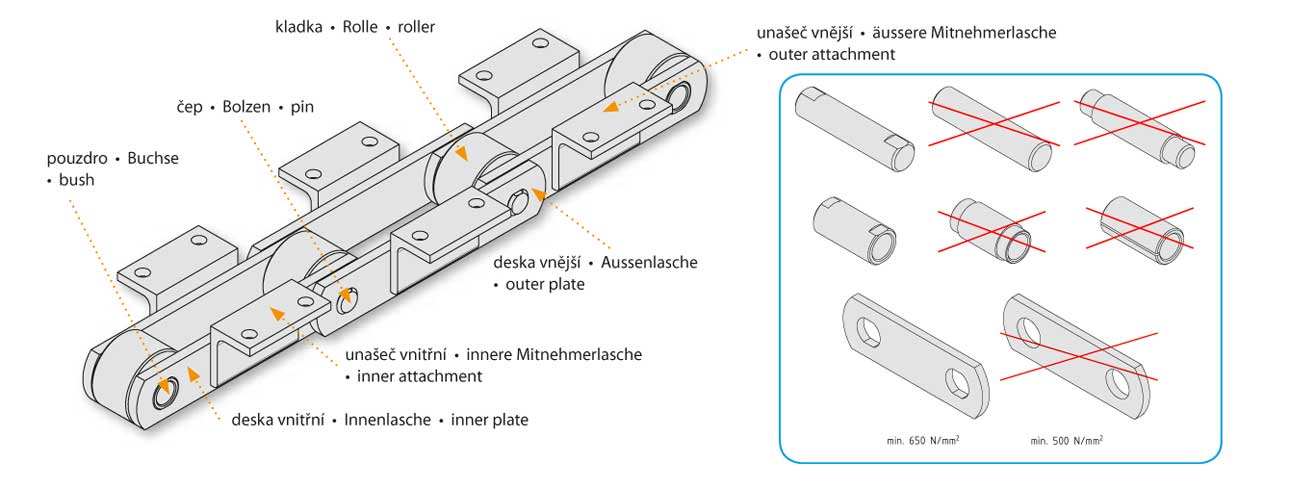

Pins - Pins produced from high-grade case hardened steel or other steel with flats against rotation. Pins always round riveted or upon request, additionally welded.

Bushes - Bushes produced from seamless tubes (not curled) with flats against rotation only, from high-grade case hardened steel to guarantee the same hardness of the inner and outer surface after the heat treatment.

Rollers - Rollers manufactured from case hardened steel to guarantee the same hardness of the inner and outer surface after heat treatment. Rollers always heat treated.

Plates - Plates produced from alloy steel to ensure the best dynamic stress resistance with the minimum tensile strength of plates of 650 N/mm2. Trouble free attachment welding.